This content is for Premium Subscribers only. To view this content, login below or subscribe as a Premium Subscriber.

Related News Articles

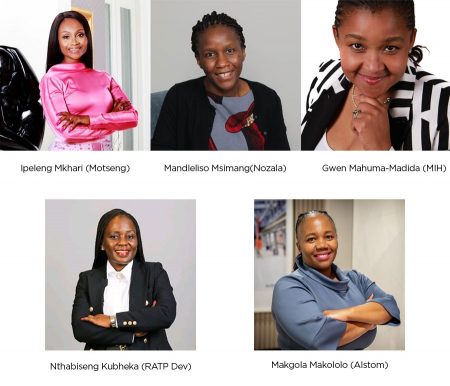

Black Women-Led Companies Driving South Africa’s Mobility Transformation

07 April 2025

SADC, South Africa

3 min

2 min

2 min

1 min

South Africa’s Department of Trade Aims to Sustain Localisation Momentum

05 April 2025

SADC, South Africa

2 min

2 min

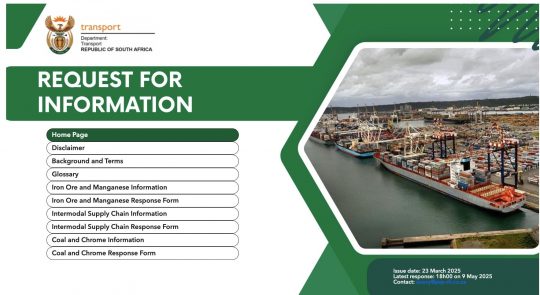

Private Sector Called to Participate in Rail and Port Sector Reform

31 March 2025

SADC, South Africa

1 min

Gautrain Expansion Set to Boost Gauteng’s Economy and Transport Network

31 March 2025

SADC, South Africa

6 min

2 min

ArcelorMittal: Update on the Long Steel Business and Cautionary Announcement

22 March 2025

SADC, South Africa

1 min

2 min